I originally planned to do this as well and did more research than I thought was necessary, but it wasn't enough.

So, the gas port on the T91 IS in the same spot as on a standard mid-length AR gas system, but it is drilled at a 30 degree angle like an AK. Whether this will correctly line up with a perfectly drilled .750 gas block is another issue since I never got this far.

The first problem now is how you are going to get the gas block to line up with the port and go past the block shoulder, as it sits about 1/2in further back than on an AR. Well, there's 3 solutions:

1. Get a shoulderless-barrel

This is the most expensive option, as I've only been able to find two companies that produce a shoulderless .750 .223/5.56 barrel (without going custom-made):

Ballistic Advantage "Hanson"-profile barrels:

https://ballisticadvantage.com/14-5-inc ... arrel.html (14.5in),

https://ballisticadvantage.com/16-inch- ... arrel.html (16in)

Bravo Company "Enhanced" barrel:

https://www.bravocompanyusa.com/BCM-14- ... wf-std.htm

Both of these will run you over $200 for the barrel alone. If you want to do this on a budget this is not the best option.

2. Get a low-profile shoulder barrel and widen the barrel hole on the gas block

This was my second idea. I found this cheap beater Bear Creek .223 Wylde barrel on sale at Primary Arms and went for it (hey, it's on sale again!):

https://www.bearcreekarsenal.com/bca-ar ... -1-8-twist

The gas block shoulder is very thin, and simply drilling out the gas block about 1/2in in to widen it to fit over the journal seemed like a good idea. I never went though with this though, but the parkerized Wolf A1 standard flash hider fits perfectly with the barrel's parkerized finish.

3. Turn down the gas block shoulder

This is the most dangerous option as this could bend your barrel and mess it up beyond repair very easily. Unless you are/can find a competant gunsmith who has experience in this I would advise not doing this.

4. Abandon the .750 barrel and just use the .708 gas block for the Wolf A1 barrel

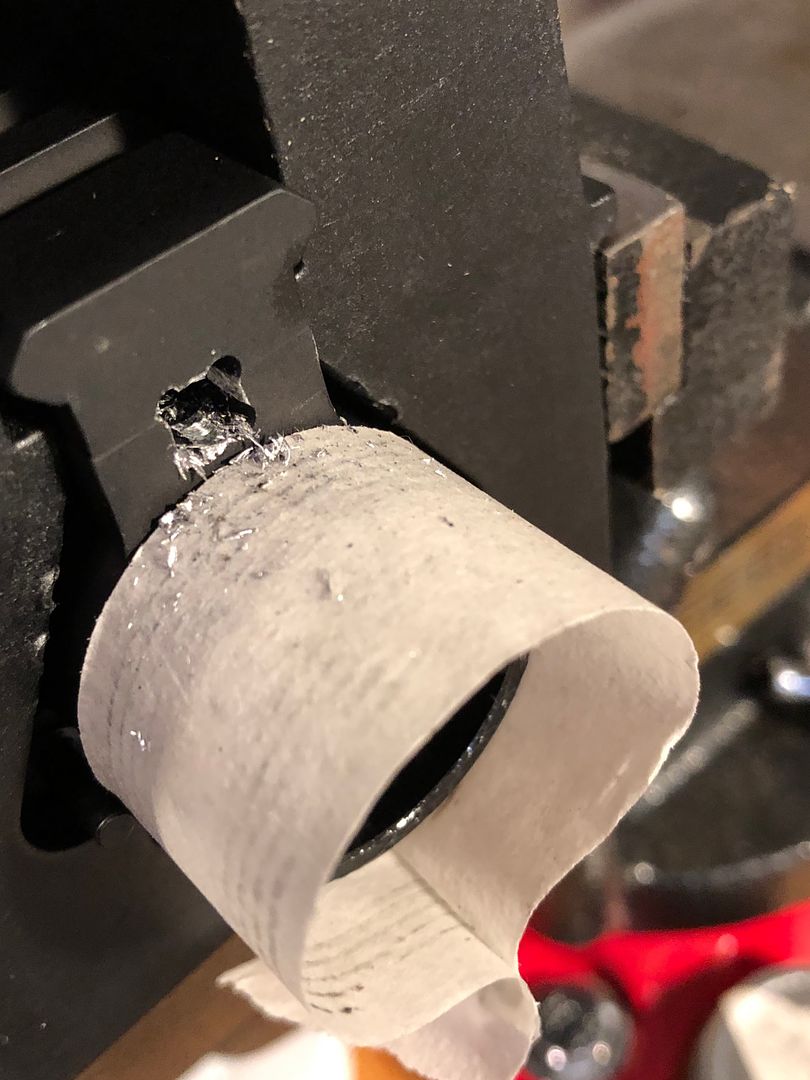

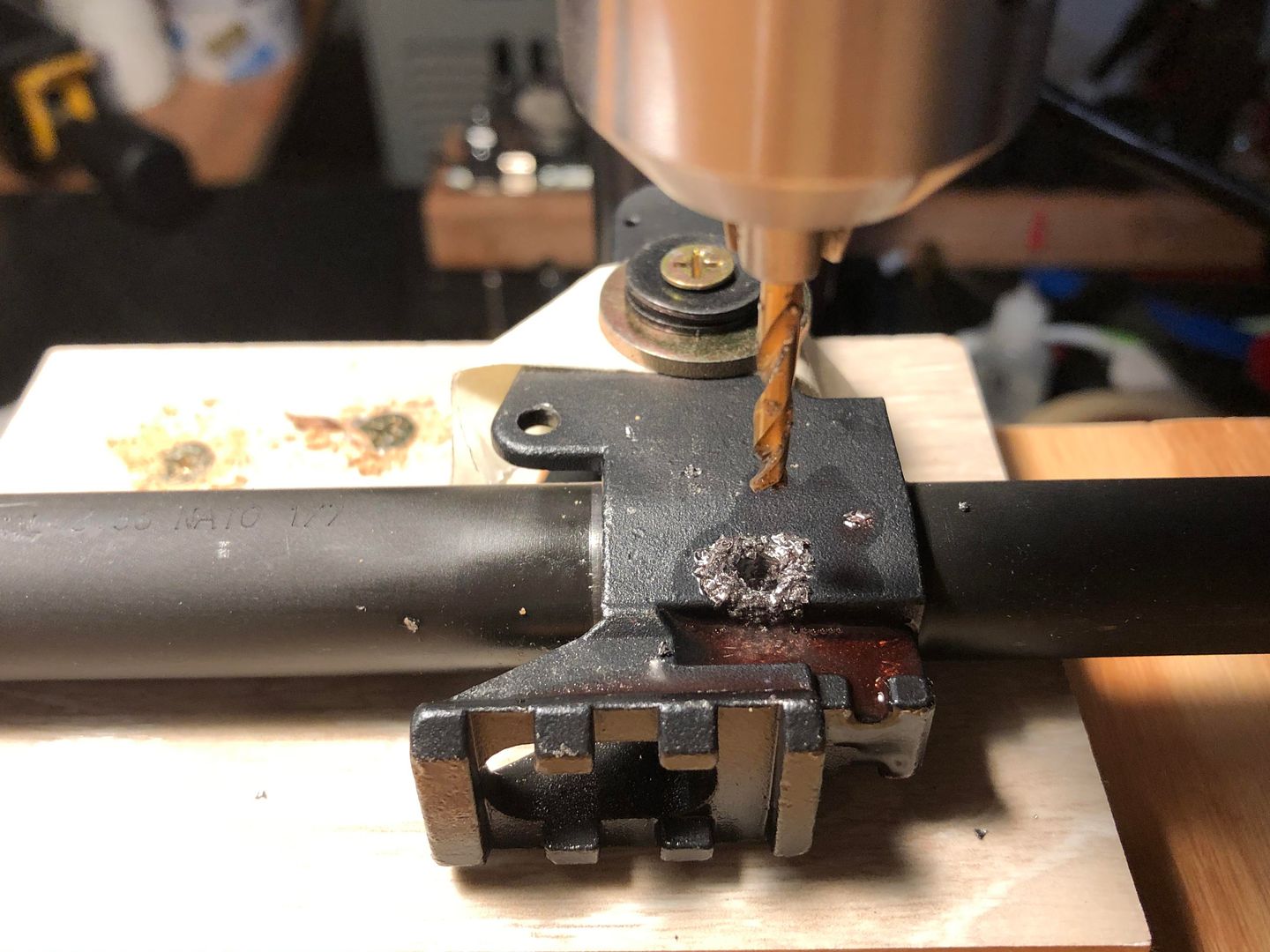

This is the option I ultimately ended up going with since it required the least amount of work. Pulling off the A1 gas block can be a pain but with the proper tools (which I didn't have) it's a 5-second job. I just went ahead and got a 14.5in barrel, slapped the Wolf mil-spec block on, pinned and welded the mil-spec flash hider to the barrel so it's a 16in barrel (no ATF tax stamp or """handgun""" requirement), filed the weld down, and finally cold-blued the filed weld and bare metal spots so it's not really noticeable from a distance.

21684621654.JPG

I wish ye luck my friend.

You do not have the required permissions to view the files attached to this post.